Horsch Avatar SD

DRILL FOR NO-TILL

A NEW CHAPTER IN NO-TILL FARMING AND A GOOD DEAL MORE

Versatile

- Can be used universally from direct drilling to cultivated soils

- Metering of up to three individual components

Robust

- High coulter pressure of up to 350 kg per individual row

- Stable and maintenance-free bearings for maximum service life

Precise

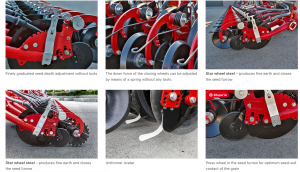

- Depth control at the individual coulter

- Closing wheels can be adjusted in an optimum way for the most different site conditions

Avatar 3 / 4 / 6 / 8 SD

COMPACT AND VERSATILE

Machine concept

The objective of the 3.16 – 8.16 SD was to develop a compact seed drill with seed coulters the depth of which can be controlled individually. The 2-bar design with a row spacing of 16.7 cm and a clearance of 33.4 cm per row provide a high operational safety even in case of many harvest residues respectively intensive catch crop populations. The large chassis tyres guarantee a soil-saving work even with a full hopper, reduce tracks and the horsepower requirement. The light-weight basic machine for sowing after conventional tillage or mulch seed allows for mounting additional weights to guarantee a safe shaping of the furrow and embedding of the seed with the SingleDisc coulter even in most difficult sowing conditions.

Versatile hopper system

The double hopper is standard equipment. You have to differentiate between the different versions:

- The 3.16 and 4.16 SD can be equipped with a triple tank – with a partition of 60 : 10 : 30 for maximum flexibility with up to 3 components.

- A third hopper with standard metering device for seed or micro-granular compounds (with the corresponding fine metering insert) can be integrated in the second hopper of the Avatar 6.15 and 8.16 SD.

Half-width shut-off or selective hosing

The mechanical half-width control is standard equipment for all machines. As an option you can chose an electrical half-width control via the ISOBUS Terminal. With a SectionControl activation the whole system can be automated. As an alternative to the half-width control the machine can be equipped with a selective hosing. In this case, one seed row (respectively one distributor tower) can be switched off.

There are two options for use:

Sowing with double row spacing (33.4 cm)

- Makes sense for example for rape

Due to the double (6.16 + 8.16 SD) or triple tank (3.16 + 4.16 SD) the seed rows can be filled with different seeds . Thus, it is guaranteed that every component is placed on the ideal seed horizon.

- Independent seed depths are possible (large grains deeply, small grains shallowly)

- Optimum for mixtures with different placement depths, without separating!

TECHNICAL SPECIFICATIONS

|

HORSCH Avatar

|

3.16 SD

|

4.16 SD rigid

|

4.16 SD

|

6.16 SD

|

8.16 SD

|

|

Working width (m)

|

3.00

|

4.00

|

4.00

|

6.00

|

8.00

|

| Transport width (m) | 2.99 | 4.32 | 2.99 | 2.98 | 2.98 |

| Transport height (m) | 3.50 | 3.50 | 3.50 | 3.31 | 3.98 |

| Length lower linkage (m) | 6.96 | 6.96 | 6.96 | 7.82 | 7.82 |

| Length adjustable drawbar linkage (m) | 7.80 | 7.80 | 7.80 | 8.66 | 8.66 |

| Axle load (kg) | 2 500 – 4 000* | 3 200 – 4 300* | 3 400 – 4 500* | 4 300 – 6 200** | 5 200 – 6 700** |

| Vertical load (kg) | 1 500 – 2 300* | 2 000 – 2 600* | 2 100 – 2 800* | 2 600 – 3 300** | 3 200 – 4 000** |

| Seed hopper capacity double hopper (l) | 3 800 | 3 800 | 3 800 | 5 000 | 5 000 |

| Feed opening double hopper (m) | per 0.66 x 0.90 | per 0.66 x 0.90 | per 0.66 x 0.90 | per 0.66 x 0.90 | per 0.66 x 0.90 |

| Filling height double hopper (m) | 3.24 | 3.24 | 3.24 | 3.26 | 3.26 |

| Feed opening triple hopper (m) | 0.66 x 0.43 / 0.66 x 0.25 / 0.66 x 1.45 | — | — | ||

| Seed hopper capacity triple hopper (l) | 3 800 (30 : 10 : 60) | 3 800 (30 : 10 : 60) | 3 800 (30 : 10 : 60) | — | — |

| Filling height triple hopper (m) | 2.95 | 2.95 | 2.95 | — | — |

| Hopper capacity micro-granular compound double hopper (l) | — | — | — | 270 | 270 |

| Number of seed coulters | 18 | 24 | 24 | 36 | 48 |

| Coulter pressure seed coulters (kg)*** | 350 | 350 | 350 | 350 | 350 |

| Seed coulter Ø (cm) | 48 | 48 | 48 | 48 | 48 |

| Closing wheels Ø (cm) | 33 | 33 | 33 | 33 | 33 |

| Depth control wheels Ø (cm) | 40 | 40 | 40 | 40 | 40 |

| Row spacing (cm) | 16.70 | 16.70 | 16.70 | 16.70 | 16.70 |

| Tyre size seed unit / waggon | 600 / 55 – 26.5 | 600 / 55 – 26.5 | 600 / 55 – 26.5 | 600 / 55 – 26.5 | 600 / 55 – 26.5 |

| Working speed (km/h) | 6 – 15 | 6 – 15 | 6 – 15 | 6 – 15 | 6 – 15 |

| Power demand (kW/hp) from | 90 / 125 | 105 / 140 | 105 / 140 | 155 / 210 | 200 / 270 |

| DA control devices | 1 (+ 1 incl. hydr. fan direct drive) | 3 | 3 | ||

| Depressurized return flow (max. 5 bar) | 1 | 1 | 1 | 1 | 1 |

| Oil quantity hydr. fan (l/min) | 35 – 45 | 35 – 45 | 35 – 45 | 35 – 45 | 35 – 45 |

| Lower link linkage | Cat. III and III / IV | Cat. III and III / IV | Cat. III and III / IV | Cat. III and III / IV | Cat. III and III / IV |

| Adj. drawbar linkage | Hitch Ø 46 – 58 mm | Hitch Ø 46 – 58 mm | Hitch Ø 46 – 58 mm | Hitch Ø 46 – 58 mm | Hitch Ø 46 – 58 mm |

| Ball-type linkage | K 80 | K 80 | K 80 | K 80 | K 80 |

* Weights of the machines with minimum equipment

** Length of the machine with lower link linkage without filling auger

*** Maximum coulter pressure depends on the equipment